0

-

An empty cart

You have no item in your shopping cart

Doztech Integrated Services specializes in volatile corrosion inhibitor (VCI) protection for metals. Providing quality corrosion preventive products and services to meet the evolving needs of global customers.

Doztech Integrated Services offers a complete line of corrosion inhibitor liquids, oils and coatings, including Nox-Rust and Evapo-Rust, to prevent rust on exposed metals and unpainted metal parts at all stages of their lifecycle – during manufacture, use storage, export, lay-up and preservation. Nox-Rust and anti-rust liquids can be sprayed or fogged into hard-to reach areas, using normal industrial application equipment.

√ A final rinse additive

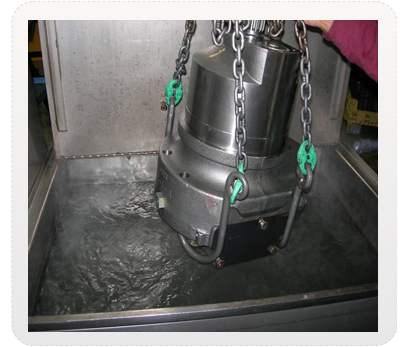

√ A fogging agent to protect internal voids and cavities in large equipment

√ Lubricant to protect equipment going into seasonal lay-up mothballing and storage

Doztech has the product and expertise to assist you

Typical applications:

For lay-up and preservation of engines in:

Selecting the proper Nox-Rust liquid depends on a number of conditions:

Nox-Rust EV9

Nox-Rust EV9 is an environmentally safe and highly effective corrosion prevention liquid

Nox-Rust EV9 is an environmentally safe and highly effective corrosion prevention liquid

If you could choose a corrosion preventive coating that works without polluting the ground or water, you’ll choose Nox-Rust EV9, an environmentally safe liquid that is engineered to be effective and ecologically responsible.

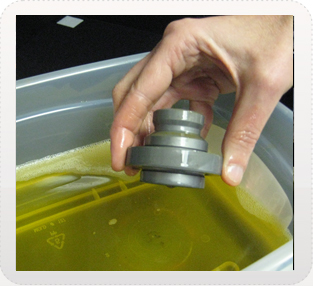

EV9 is a vegetable (soybean) based, biodegradable protective coating. It is made with edible, food grade soybean oil which has been bleached and deodorized. It is very resistant to spoiling and going rancid over time. EV9 also contains proven Daubert corrosion inhibitors.

It is water-displacing, and has the viscosity to reach voids and recesses of intricately machined metal parts.

Low-VOC, non-toxic, non-flammable, and completely biodegradable.

It can be removed, if required, with high pressure steam or a hot alkaline wash. And because it is formulated with organic materials, it can be disposed of down the drain.

If you store or ship pipes, tubes, engineered parts, fabricated metals, transport equipment or similar, EV9 is the right coating for physical corrosion protection.

Nox-Rust 1100

A lubricating oil and corrosion preventive to protect metals in closed systems such as fuel tanks, hydraulic and coolant circulating systems. Prevents rust caused by condensation build-up inside equipment during lay-up and preservation. Removal not required. Ready to use straight out of the pail or drum.

Nox-Rust 1101

Use in systems where a combination of metals are present, including steel, iron, zinc, brass and aluminum. Typical examples of “closed” systems include fuel tanks, gear housings, storage tanks, clutch compartments, cylinders, crankcases, transmissions, hydraulic and coolant circulating systems, and metal containers.

Nox-Rust 1101 can be used full strength in ferrous and non-ferrous metal systems. Corrosion protection lasts up to 1 year. It may also be fogged into shipping cases to protect unpainted auto and truck body sections during shipments. Sold in pails, drums, and aerosol cans.

Nox-Rust 1200DC

Environmentally safe, silica-free water solution for closed systems. Apply water-soluble Nox-Rust 1200DC by fog or spray. The silica-free liquid leaves no residue. Contains no phosphates, heavy metals or nitrites. Use it to preserve equipment and piping systems that need hydrostatic testing prior to shipping or storage. It provides continuous corrosion protection for ferrous metals, and is compatible with copper and galvanized steel. The clear, odorless liquid typically does not need to be removed prior to equipment restart.

Nox-Rust 4101

Nox-Rust 4101 protects steel in areas where the acid fumes are present, commonly found in pickling operations. The non-staining, water-displacing, light oil is easy to apply by dip, spray, flow coat or brush. The soft, waxy film protects steel and zinc, and is also compatible with non-ferrous metals.

Nox-Rust 9800

Water-soluble Nox-Rust 9800 VCI liquid is designed to spray or fog into closed spaces such as turbines, pipes, and tanks. The clear, amber liquid is moisture-absorbing, finger-print removing, and ready to use. Provides continuous protection against corrosion and oxidation of steel, iron, zinc, and aluminum. Removal is not required.

Nox-Rust 5100

Nox-Rust 5100

Ideal for general metal preservation, indoor or outdoor. Use it with or without other barrier covers in domestic and export shipment and storage. Apply Nox-Rust 5100 by dip, spray or brush. It dries to a black, dry, firm film that can be handled after 3-6 hours and sets up in 12-24 hours. Lasts 1-3 years in outdoor, unprotected storage; 3-5 years in protected outdoor storage.

Nox-Rust 5200

Apply Nox-Rust 5200 on exposed metals and unpainted metal parts. The brown, grease-like film dries as a semi-firm coating in 12-24 hours. Protection lasts 3-6 months on equipment stored outdoors, up to 5 years if stored indoors. Ideal for machinery, instruments, bearings and steel parts; compatible with non-ferrous metals. Sold in pails, drums and aerosol cans.

Nox-Rust 5300

Nox-Rust 5300 is a brown, oily film that displaces water and saline solutions to keep corrosion from forming on metal surfaces inside closed systems. Completely miscible with lubricating oils. Apply by dip, spray or brush. It dries as an oily film that can be handled after 3-6 hours. Corrosion protection lasts up to 12 months. Sold in pails, drums, and aerosol cans.

Nox-Rust 9900

Environmentally safe Nox-Rust 9900 is a water-based barrier coating with corrosion protection for steel equipment, assemblies and parts. It will protect engine blocks, gears, tool and dies, valves, machined parts, automotive and production parts between the shop floor and the shipping dock. It’s the ideal alternative to traditional oil-based corrosion preventives.

Nox-Rust 9900 is a high quality and environmentally safe barrier coating for ferrous and non-ferrous metals, including copper and brass. This low VOC, emulsified coating contains a superior blend of inhibitors with no solvents, petroleum oils or harmful chemicals. The firm clear film product can be applied by spray, dip or brush and will provide both indoor and limited outdoor storage protection.

Nox-Rust 8500 exterior barrier coating

Water-based Nox-Rust 8500 is a hard acrylic emulsion film for a variety of metal surfaces including aluminum and chrome. Water-based, clear Nox-Rust 8500 is a non-removable coating ideal for use in harsh (acidic) environments. Apply by dip, spray or brush. It dries as a tack-free exterior coating that will not pick up dust or dirt. Non-staining. Removal is not required, but it may be removed with soap and water for up to an hour after applied.

Nox-Rust 5400

Nox-Rust 5400

Nox-Rust 5400 is a multi-metal inhibitor for general industrial use. Used as a wash, it leaves behind a lubricant and corrosion preventive film. It will not interfere with assembly sealers, adhesives, painting, welding, and cleaning solutions. Easy to remove by conventional cleaning methods. Approved for use in automotive manufacturing — cold rolled steel, sheet metal stamping, automotive parts. Sold in pails, drums, and aerosol cans.

Nox-Rust 7100

Does your company manufacture springs, machine tools, compressors, gears, drive shafts, precision parts, watch components, taps, drills, and parts for refrigeration, aviation or transportation? Any plant operation with a stamping operation using water-base cutting fluids likely needs Nox-Rust 7100.

It is a light, water-displacing, transparent oil that repels residual cutting fluids. It will not clog stamping dies, a crucial benefit. It is also non-staining, another important quality for in-plant or cross plant processing.

The light oil dries to a soft dry film which is barely noticeable, except for the sparkling luster it puts on treated metal. Parts remain protected for 3-6 months indoors. Apply by dip, spray or brush. In most cases, removal is not necessary.

Nox-Rust 7800

Experienced users of Nox-Rust 7800 call it the best all-purpose lubricant they have ever tried! Shop mechanics, for example, use it for temporary corrosion protection, un-seizing a stubborn nut to keeping machines running smoothly.

Nox-Rust 7800 is a water displacing, low viscosity lubricant and corrosion preventive liquid. It will protect both ferrous and non-ferrous parts during storage and covered transit at low film thickness. No mixing or preparation is required.

It has the unique capability to creep and penetrate into very tight and hard-to-reach spaces. It remains fluid at -70°F, which is why the military uses it a gun oil for firearms in cold climates.

Nox-Rust 7800 is also ideal in transit and transportation industries, machined parts and even routine maintenance shop use. Apply it by spray, dip or brush. Corrosion protection is effective up to 12 months. If removal is required, use mineral spirits, hot alkaline wash or high pressure steam. Doztech Integrated Services is the trusted global provider of liquid vci products

Nox-Rust 9300

Nox-Rust 9300

Nox-Rust 9300 is an all-purpose corrosion inhibitor additive for final stage rinse. It retards corrosion during shipment and storage of machined parts, tools, treated steel and assembles. Can be diluted with water or petroleum solvent. The light, transparent liquid can also be applied by dip, spray or brush. It dries as a thin, oily emulsion. Protection lasts 3-9 months.

Nox-Rust 9700

Nox-Rust 9700 is a synthetic, water-based fluid designed as a final and in-process RP additive. Removes dirt and debris from steel before mill oils are applied. Add to cutting fluids, metal working fluids, or final stage rinse. It is water-displacing, and compatible with zinc and copper.